LOW NOx BURNER

LOW NOx BURNER FEATURES

■ Low NOx emission (60ppm, combustion air temp @ ambient)

■ No moving parts for reliable service.

■ Low draft loss enabling low power loss of F/D fan

■ Able to run with low excess air (O₂2%)

■ BP-108 code applied

■ Suitable for vertical, horizontal or angles application

■ Burner design developed using the test facilities

■ Many reference lists for industrial & power boilers and hot oil heater

■ No moving parts for reliable service.

■ Low draft loss enabling low power loss of F/D fan

■ Able to run with low excess air (O₂2%)

■ BP-108 code applied

■ Suitable for vertical, horizontal or angles application

■ Burner design developed using the test facilities

■ Many reference lists for industrial & power boilers and hot oil heater

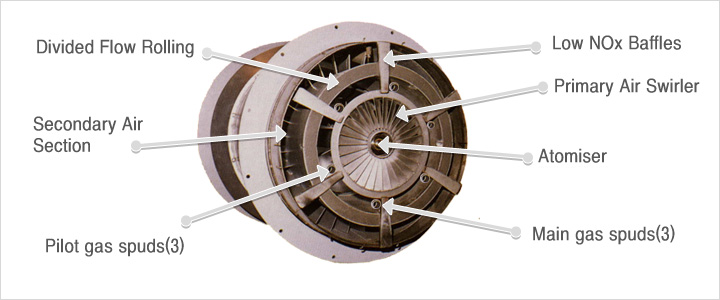

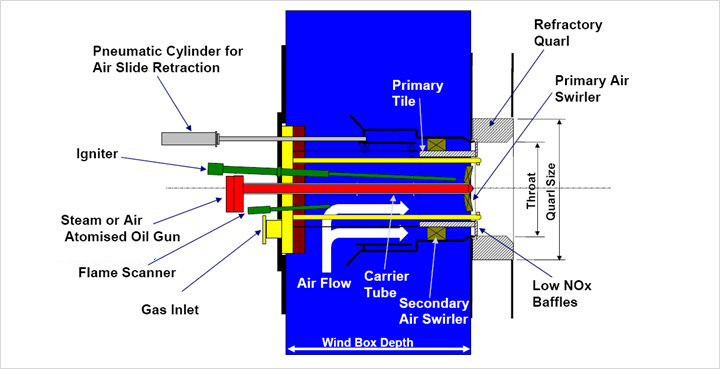

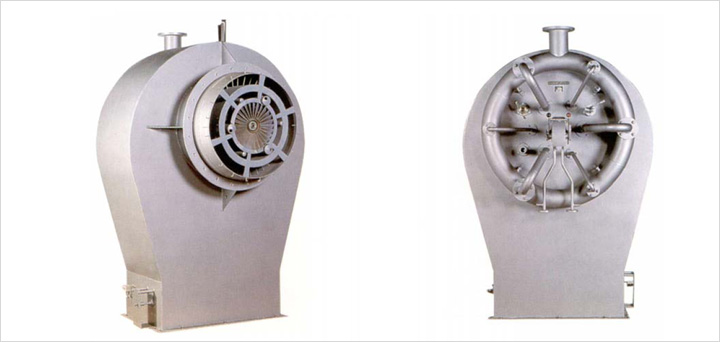

LOW NOx BURNER STRUCTURE

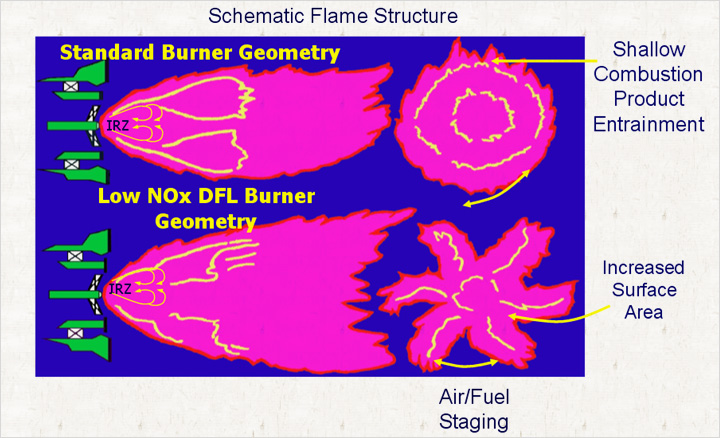

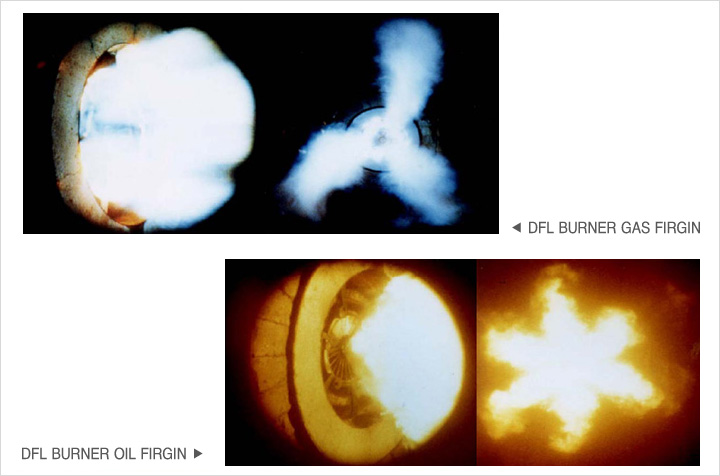

LOW NOx BURNER FLAME

SPECIFICATION

| DESCRIPTION | 단위 | 5T/H | 8T/H | 10T/H | 15T/H | 20T/H | 25T/H | 30T/H | 35T/H | 40T/H | 50T/H | |

| BURNER MODEL | DFL 352 |

DFL 400 |

DFL 435 |

DFL 480 |

DFL 535 |

DFL 600 |

DFL 650 |

DFL 705 |

DFL 755 |

DFL 870 | ||

| BURNER TYPE | OIL only : STEAM(AIR) JET TYPE, LOW NOx GAS only : GAS MANIFOLD & MULTI SPUDS or CENTER GUN, LOW NOx GAS/OIL dual : STEAM(AIR)JET & MULTI SPUDS, LOW NOx | |||||||||||

| Kind of Fuel | B-C OIL, DIESEL OIL, LNG, LPG, OR H2 GAS | |||||||||||

| BURNER CAPACITY |

OIL MCR | Kg/HR | 375 | 600 | 750 | 1125 | 1500 | 1875 | 2250 | 2625 | 3000 | 3750 |

| GAS MCR | Nm3/HR | 385 | 615 | 770 | 1125 | 1540 | 1925 | 2350 | 2688 | 3080 | 3850 | |

| OIL PRESS. AT BURNER INLET |

Kg/cm2 | MAX. 10-12 | ||||||||||

| GAS PRESS. AT BURNER INLET(MCR) |

Kg/cm2 | MIN. 0.2 (GAS TRAIN INLET : 0.4~0.9k) | ||||||||||

| ATOM. STEAM PRESS | Kg/cm2 | 5.5 or 8.3 (CONSTANT PRESS. TYPE) | ||||||||||

| ATOM. STEAM CONSUMPTION |

Kg/HR | 4-6% / FUEL OIL | ||||||||||

| FUEL OIL TEMP. AT BURNER INLET |

130 oC / 15cst (B-C OIL FIRING) | |||||||||||

| BURNER DRAFTLOSS AT MCR |

mmAq | 100 | 105 | 130 | 145 | 160 | 160 | 170 | 180 | 190 | 200 | |

| EXCESS AIR RATIO AT MCR |

% | 10 | ||||||||||

| TURN DOWN RATIO | 5:1 | |||||||||||

| FLAME SIZE | LENGTH | mm | 2800 | 3250 | 3450 | 4018 | 4410 | 4704 | 5096 | 5341 | 6000 | 6400 |

| DIA | mm | 1190 | 1360 | 1440 | 1700 | 1850 | 1950 | 2150 | 2250 | 2480 | 2600 | |

* Emission guarantee (O2 4% base)

- LNG firing : NOx 60 ppm, CO 50 ppm

- B-C oil firing : NOx 180 ppm, DUST 80 mg/Sm3

- Emission guarantee depends on the boiler conditions and fuel analyses

* Burner model can be changed according to the combustion air temperature

- LNG firing : NOx 60 ppm, CO 50 ppm

- B-C oil firing : NOx 180 ppm, DUST 80 mg/Sm3

- Emission guarantee depends on the boiler conditions and fuel analyses

* Burner model can be changed according to the combustion air temperature

BURNER DESIGN

For many years Hamworthy have been in the forefront of burner design and recognised as a burner supplier of equipment capable of high combustion efficiency. Burners in operation have met stringent limits on particulate emissions, coupled with low excess air operation for maximum efficiency and acid corrosion control. As its Pool works it has large combustion test facilities, enabling development programmes and trials to be effected with full scale burners. The test rigs are also available for customer demonstration. Fully instrumented for the measurement of NOx, oxygen, particulates and carbon monoxide, it provides one of the most comprehensive research and development installation throughout the Combustion Industry. More recent demands to reduce the level of nitrogen oxides being emitted, without increasing particulates emissions or compromising efficiency, have not gone unheeded. These have enabled Hamworthy to meet levels demanded not only by the U.K. 'Environmental Protection Act', but also more demanding and tougher standards set it other European countries and North America.